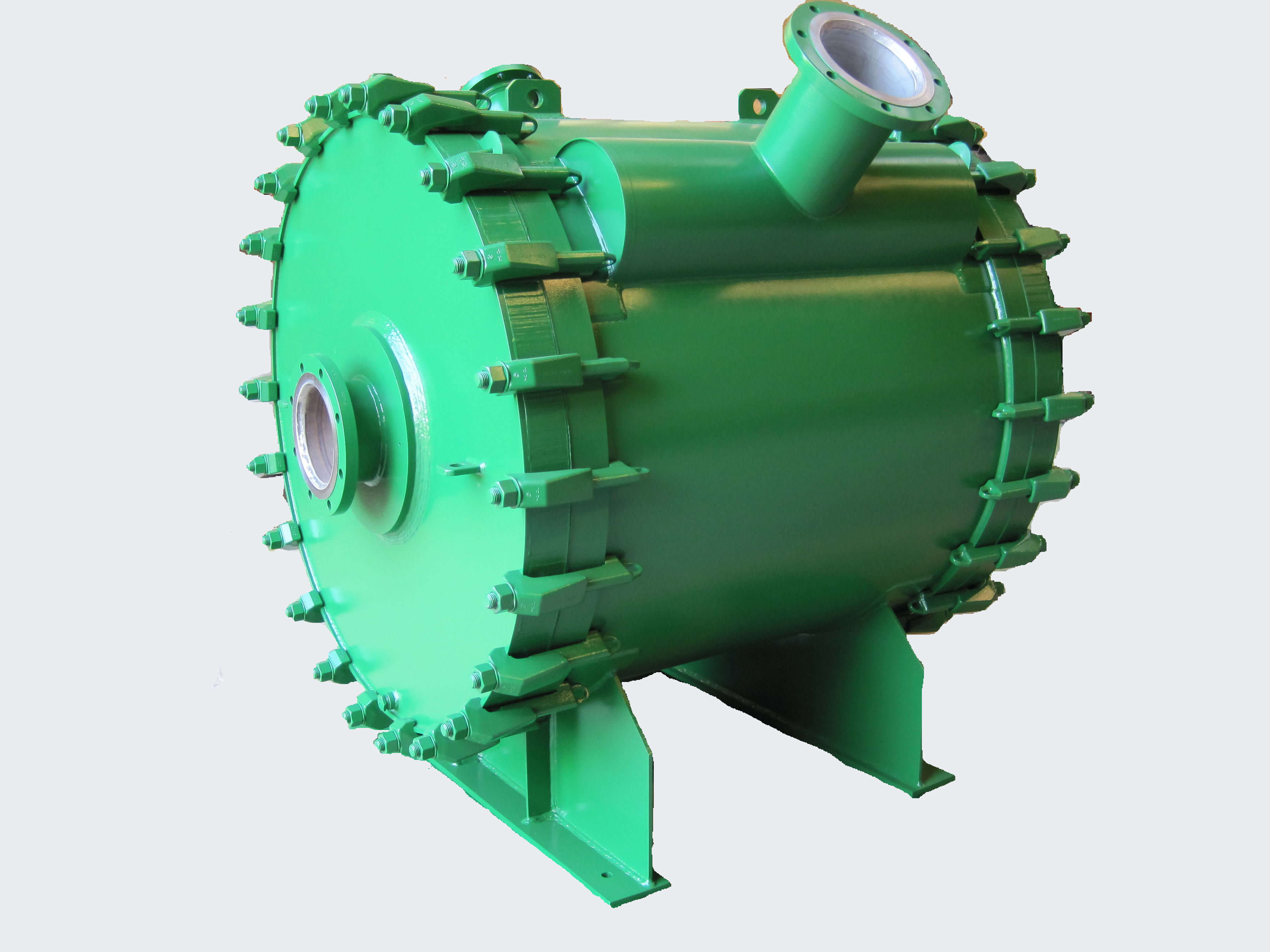

Welded plate Heat Exchanger

WELDED BOX HEAT EXCHANGER

EASY TO CLEAN

Welded heat exchanger is easy to clean with hydro pressure water jet.

CLOSE TEMPERATURE APPROACH

Corrugated plates caused h high K value, welded box can reach a very close temperature approach.

ENERGY SAVING

High heat transfer value (K value) which leads to optimise design to save in energy cost.

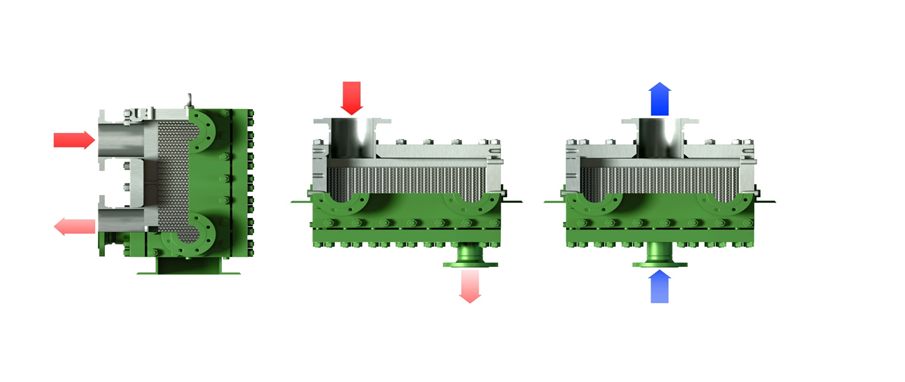

LOW MAINTENANCE COST

Since it can maximize heat transfer surface both vertical and horizontal. Less gasket.

COMPACT SIZE

Regarding high K value and maximizing surface area of spiral heat exchanger can replace 3 traditional Shell & Tubes products and less footprint.

FULL INSPECTION OF THE HEAT TRANSFER AREA

After opening 4 panels, the whole heat transfer area can be access to inspection.

SPIRAL HEAT EXCHANGER

Nexson are made of 2 concentric channels on which spacer pins are welded to form the channel's gaps. Each channel gap and the width of the channels are selected to meet each Customer's specific requirement and working conditions. It permits to take into account the flow rates, the sizes of the particles for fouling fluids and the pressure drops. These spacer pins facilitate turbulent flow in each channel